Artificial Intelligence Discovers “Toledano Steel” of the Future | technology

Thousands of years ago, humans imposed themselves on nature or other humans by mastering the art of smelting and mixing metals: the Copper Age was followed by the Bronze or Iron Age. Modern steel is the basis of the industrial revolution of the late eighteenth and nineteenth centuries. In the twentieth century, aluminum, titanium or superalloys allowed huge technological leaps in cars, planes, missiles, prosthetics … some of its properties.

A group of researchers from the most prestigious European technical research centers, from the Max Planck Institute for Metallurgical Research to the Delft University of Technology, passing through the Royal Institute of Technology in Stockholm, has created a machine learning system (machine learning, in English) capable of diving between millions of combinations between the different elements of the table periodic, finding 1,000 candidates with the properties that interest them and analyzing them in search of those that would theoretically have a low coefficient of thermal expansion (the expansion or contraction of a substance with cold or heat). As published in the magazine Sciencesfound four new alloys with modulus equal to or less than most of the heat immunogenic formulations used to date.

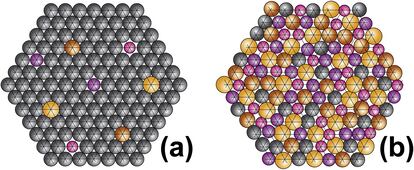

Until a few years ago, an alloy was essentially a mixture between a parent metal and small concentrations of other elements from the periodic table. The rules of mineralogy could have gone further. IMDEA Materials Director, José Manuel Torralba, explains this by comparing coffee with an iron-based alloy. “By dissolving the sugar, you get a single liquid with different properties than those of coffee and sugar separately. It’s the same in alloys, but there are limits to the proportion of other elements you can add to iron before there’s a precipitate that’s no longer part of the main alloy and generally aggravates.” its characteristics”. It all exploded in 2004: “Then two independent groups combined five items in similar proportions, and saw that they constituted one unique solution,” he says. This opened a new era in the science of materials, namely, high-entropy alloys. But there was a new challenge: finding new combinations between a major element and smaller quantities of two or three others (steel being iron with three or four additives) was a difficult, but possible task. Prior to this time, adding many alloying elements in large proportions was a problem. In those with high entropy, it is estimated that the potential new compositions of dozens of elements and their different concentrations exceed 10 °C. An amount that is impossible for humans to handle, but less than that for machines.

Compared to traditional methods, machine learning is more efficient, saving time and effort.

Xiuan Rao, a scientist at the Max Planck Institute for Metallurgical Research

Max Planck Institute researcher and first author of the research, Xiuan Rao, comments on the main advantage of his artificial intelligence (AI) system: “Compared with traditional methods, machine learning is more efficient, saving time and effort,” he says. For most of history, the discovery of new alloys with better properties was based on trial and error, knowledge accumulated by craftsmen or direct chance. Such is the case of the Toledo Steel Company, whose swords have been feared for centuries. As Carlos Capdevilla, director of the National Center for Research on Metals (CENIM-CSIC), recalls, “They forged it with coal from nearby mountains, which contains more carbon than other swords in Europe, giving it more hardness.” Materials science currently relies on computer programs and models that memorize calculations and predict results, but the critical work remains human.

Rao and his colleagues’ AI system consists of three basic steps. They first use a model that generates new mixtures from a database that researchers have previously collected. He elaborates: “This is because high-entropy alloys have a huge spectrum of compositions and it is almost impossible to cover all possible compositions.” In the second step, they use another model to predict the properties of the constructs they obtained in the first. In a final step, the system scores the candidates (in this case 1000) by combining the expected coefficient of each with the degree of novelty of each.

From 19 Nobel to 21 systems

And so they came up with four new alloys that they compared with Invar. It is an alloy containing in its original alloy 64% iron, another 36% nickel and small amounts of manganese, carbon and chromium. Discovered at the end of the 19th century, its discovery was awarded the Nobel Prize for its Swiss creator Charles-Edouard Guillaume, and it had a very low coefficient of thermal expansion. Unaffected by thermal changes, it has been and remains essential in the design of precision instruments, clocks, pendulums, kinematic valves, telescope optics mechanics… Two of the alloys created by their intelligence system are equal to inverse alloys, and two others “have the lowest modulus,” Rao asserts. for thermal expansion of high or medium entropy alloys.

Stefan Bauer, a researcher at the Royal Institute of Technology in Stockholm and one of the senior authors of this paper, recalls in a note: “Machine learning models have been incredibly successful when unlimited amounts of data are available, for example in video games. .However, in the world In real life, it is much more difficult to find use cases where AI makes a difference. It is very exciting to see that not only are the predictions tested in simulations, but new alloys have been created and physically displayed.” Having proven its value through thermal expansion, the scientists plan to use their machine learning system to explore other properties, such as magnetism, in other materials.

John Miguel Sanchez is a researcher in advanced materials at Technia. A few years ago, he did his doctoral thesis on high-entropy alloys. When asked about potential properties other than thermal expansion of these alloys and their potential applications, we are almost out of paper. “There are many alloys that have improved traditional alloys in many aspects. Some scientists compare their discovery to the discovery of steel.” Some have better thermomagnetic properties. Others have better cooling performance, which is key to fuel storage. It is also reminiscent of a high-entropy titanium alloy that outperforms the best titanium alloys used in prosthetics today in corrosion resistance. “Finally, one of the most important and best understood by humans is better structural properties (car parts, for example) especially at higher temperatures.” Hence, Sanchez believes the importance of this business. “Applying artificial intelligence to discover new alloys is something completely new. The discovery of new materials with these methods is a major advance,” he says.

Capdevila, Director of CENIM, comments that discovering a new alloy or improving the properties of an existing one by slightly modifying its composition has advantages. It gives an example of the cover they will put in the Santiago Bernabéu football stadium. Stainless steel is characterized by high reflectivity and without its modification, “the temperature in the surrounding stands will be very high.” However, the alloy they will put in will neutralize most of the heat. “Discovering a new alloy would be for a four- or five-year doctoral thesis, and now the machine will do it in a few days.” But Capdevila maintains that the human part is still there. “It’s computing power, but I, humans, tell it the criteria that matter to me.”

Torralba, director of IMDEA Materials, is convinced that high-entropy alloys are beginning a new era. They promise improvements in much needed properties, such as certain magnetic properties, higher resistance to corrosion, greater tolerance to temperature extremes or thermal changes…and remember that one of the barriers to developing fusion energy is the lack of a material that can withstand the high temperatures generated in a reactor. merger. “In all technologies, progress depends on the presence of the necessary materials,” he recalls.

You can follow country technology in Facebook s Twitter Or sign up here to receive Weekly Bulletin.